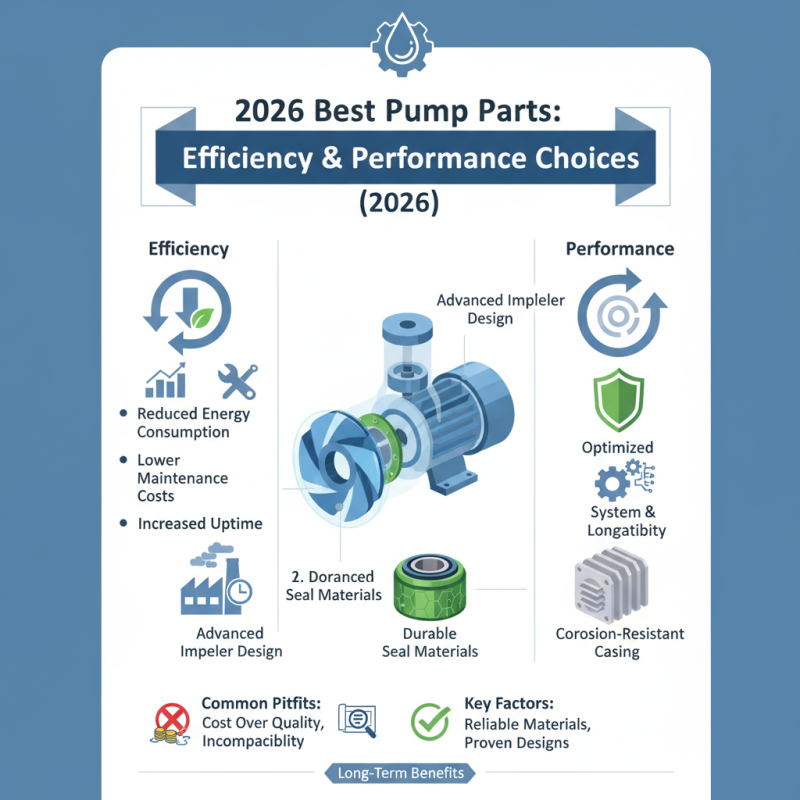

The right pump parts are crucial for optimal efficiency and performance. In the world of industrial and agricultural systems, choosing the best components can make a significant difference in energy consumption and operational longevity. The market is filled with various options, each promising superior results.

However, many users overlook essential features when selecting pump parts. Common pitfalls include prioritizing cost over quality and ignoring compatibility with existing systems. These choices can lead to inefficiencies, increased maintenance costs, and reduced uptime.

Focusing on reliable materials and proven designs is vital. It may require more research, but the long-term benefits are undeniable. In this exploration of the 2026 best pump parts, we will delve into options that prioritize both performance and efficiency. We will highlight aspects that might be neglected, yet are necessary for sustained success.

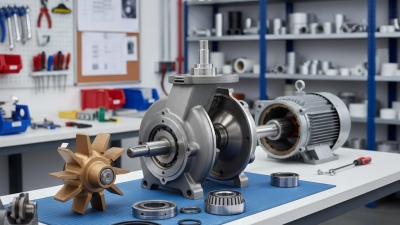

When discussing pump parts, efficiency and performance stand out. Each component plays a critical role in ensuring a pump operates smoothly. From impellers to seals, their design impacts how effectively a pump performs. A well-designed impeller can increase flow rates but may wear faster if material choice isn't optimal.

Tips: Regularly inspect impellers for signs of abrasion or damage. This simple action can extend pump life.

In addition to impellers, seals also significantly influence efficiency. Leaks can severely hinder performance and lead to increased energy consumption. A small but effective seal can make a big difference in reducing unwanted flow loss.

Tips: Use high-quality seal materials to avoid frequent replacements. It's an investment in reliability.

Understanding each part's function helps in making informed choices. Sometimes, minor changes in parts can yield major results. Beware of potential mismatches between parts. Choose compatible components wisely to ensure overall performance.

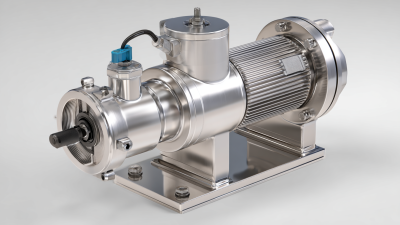

When selecting pump parts for optimal performance, a few key factors come into play. Material choice is crucial. Using corrosion-resistant materials can extend the lifespan and efficiency of the pump. In a study, pumps made from high-grade stainless steel showed a 30% increase in durability compared to lower-grade options.

Another important factor is the pump design. Centrifugal pumps often offer high efficiency in fluid transfer. According to recent reports, the efficiency rates can exceed 85% when the right impeller size is selected. Proper alignment is equally important, as improper alignment can lead to premature wear. Regular checks can help maintain performance levels.

**Tip:** Always analyze the flow rate requirements. This helps in selecting the right pump size.

Maintenance practices also play a significant role. Regular inspections can identify worn-out parts before they cause significant issues. One report highlighted that proactive maintenance reduces overall operational costs by about 25%.

**Tip:** Consider implementing a scheduled maintenance program. It helps to avoid unexpected downtimes.

Selecting the right pump parts involves assessing material, design, and maintenance needs. Ignoring any of these can lead to inefficiencies and performance drops. Reflecting on these aspects can yield better operational outcomes in the long run.

| Part Type | Material | Efficiency Rating | Durability Score | Cost ($) |

|---|---|---|---|---|

| Impeller | Stainless Steel | 90% | 8/10 | 150 |

| Seal | Ceramic | 85% | 9/10 | 70 |

| Pump Housing | Cast Iron | 88% | 7/10 | 200 |

| Bearing | Bronze | 92% | 8/10 | 90 |

| Volute | Polypropylene | 86% | 6/10 | 110 |

When it comes to high-performance pump parts, material selection is crucial. Many manufacturers prefer stainless steel for its durability and resistance to corrosion. This material can withstand harsh environments. However, it's important to evaluate its weight and cost in relation to the application. Sometimes, lighter materials may offer better efficiency, but at the cost of longevity.

Another common choice is plastic, especially for specialized components. Plastic parts are lightweight and can be molded into complex shapes. This flexibility can enhance performance in certain designs. Still, plastic's vulnerability to chemicals can be a significant drawback. Some operations may expose pump parts to substances that degrade plastics, leading to frequent replacements.

In the world of pump manufacturing, composite materials emerge as a fascinating option. They combine the best properties of different materials. For example, a composite can offer the strength of metal while remaining lightweight. However, these materials are often more expensive and require advanced techniques to produce. Manufacturers must weigh the benefits against the costs and limitations.

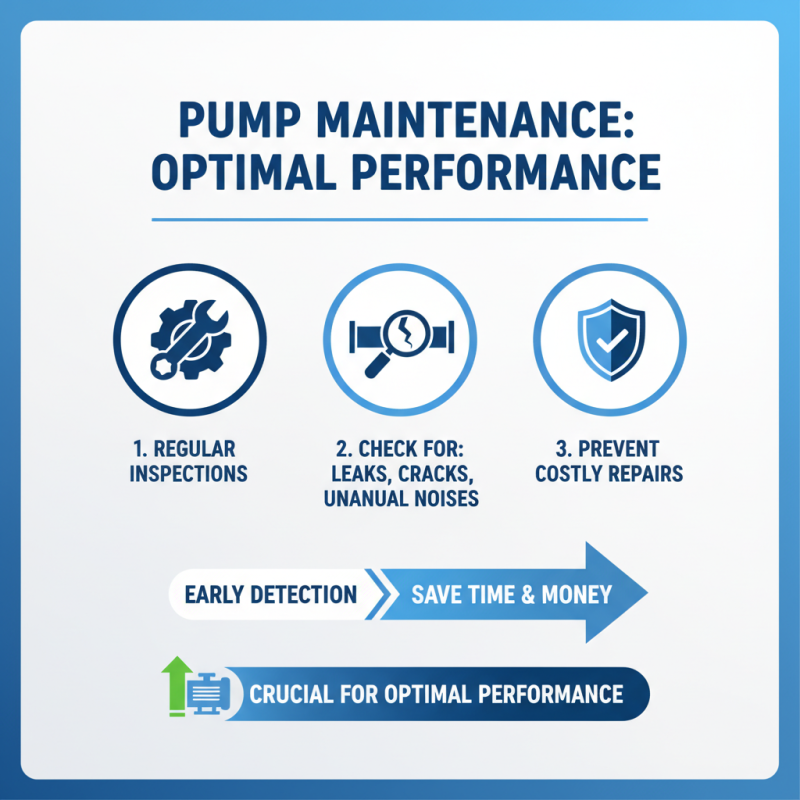

Maintaining pump parts is crucial for optimal performance. Regular inspections can reveal wear and tear. A simple check can save time and money later. Look for leaks, cracks, and any unusual noises. These signs indicate the need for maintenance or replacement.

Lubrication is a key factor in pump longevity. Proper lubrication reduces friction and prevents overheating. However, over-lubrication can lead to buildup and other issues. Finding the right balance is essential. Routine cleaning can also enhance efficiency. Residue can block essential components, causing failures.

Monitoring the operating environment is important. High temperatures or corrosive substances can wear down parts faster. The right environment prolongs the life of components. Educating staff about potential problems helps too. They should know how to spot issues early. Mistakes happen, but learning from them is vital. Regular training can reduce human error in maintenance tasks.

In the world of pump technology, innovations focus on enhancing efficiency and performance. Recent advancements emphasize materials that reduce wear and improve longevity. These materials withstand demanding conditions, ensuring pumps operate smoothly.

Here are some tips for selecting pump parts: consider components that offer better corrosion resistance. This increases the lifespan of parts. Look for designs that enable easier maintenance. Simpler maintenance means less downtime.

Many users often overlook the importance of compatibility. Always check if new parts fit existing systems. Misalignment can lead to inefficiencies. Small details matter significantly in achieving optimal performance. Aim to strike a balance between cost and quality. While cheaper alternatives may seem appealing, they often lead to unexpected failures.